Mitsubishi Fuso Unveils

|

| • | Targeting Highest Level Environmental and Economical Performance |

| • | Adopting New Engine “4P10” with BlueTec® System |

| • | The World’s First Dual-Clutch-Type Transmission for Commercial Vehicles, DUONIC |

| • | Powertrain to Debut in New Light-Duty Truck Line Now in Final Stages of Development |

Kawasaki – Mitsubishi Fuso Truck and Bus Corporation (MFTBC), one of Asia’s leading commercial vehicle manufacturers and an integral part of Daimler Trucks, today unveiled an advanced, new powertrain for light-duty trucks. Designed to achieve the highest levels of environmental performance and overall economy while featuring various industry “firsts,” the new powertrain will debut in the next generation Mitsubishi Fuso light-duty truck line. This new powertrain consists of a light and highly efficient three-liter “4P10” diesel engine with low fuel consumption; the BlueTec® emissions reduction system combining an urea selective catalytic reduction (SCR) system and regeneration-control diesel particulate filter (DPF), incorporated in a light-duty truck for the first time in Japan; and the DUONIC dual-clutch transmission, the first ever use of this type of transmission in a commercial vehicle. Based on the combined performance of these systems, the new powertrain is expected to contribute to an overall 8-10% reduction in fuel consumption compared to the previous JP05 vehicle, based on internal testing. Development of the new powertrain started in 2006. MFTBC takes the lead in developing and producing light-duty trucks within Daimler Trucks. “Mitsubishi Fuso’s development targets with the new light-duty powertrain were to achieve low emissions, low fuel consumption, high reliability and superior drivability,” said Prof. Dr. Eike Boehm, MFTBC Vice President of Product Engineering. “We believe the new powertrain with the 4P10 engine, BlueTec® emissions reduction system and DUONIC transmission strongly fulfills and exceeds those targets. This powertrain will serve as the powerful and efficient ‘heart’ of Mitsubishi Fuso’s upcoming new light-duty truck generation. Prof. Dr. Boehm added, “With the proven BlueTec® emissions reduction system and overall fuel efficiency of the engine, the new powertrain also shows MFTBC’s strong commitment to reduce the environmental impact of our products.” |

| Main Characteristics of New Light-Duty Powertrain |

| • | Scheduled to comply with Japan 2010 new Long-Term Emission Regulations and various U.S. and European emission regulations. |

| • | Featuring the new 4P10 engine developed to achieve lightweight performance, high efficiency, and low fuel consumption. |

| • | BlueTec® system adopted in a light-duty truck for the first time in Japan to achieve low fuel consumption and clean emissions. |

| • | First commercial vehicle to adopt a dual-clutch transmission to achieve high power performance. |

4P10 Engine |

DUONIC Dual-Clutch Transmission |

| Product Details |

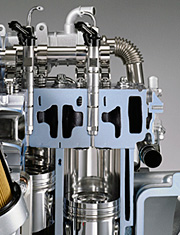

| 1. Newly developed light-duty engine 4P10 |

The newly developed 4P10 engine is a three-liter variable geometry (VG) turbo diesel engine with in-line four cylinder, adopting DOHC4 valve structure. Flat torque characteristics and higher revolutions significantly enhance drivability. The new 4P10 is also much lighter than its predecessor. The combination of optimum tuning for the Japan market and BlueTec® system enables cleaner gas emissions and lower fuel consumption. The 4P10 engine has been developed jointly by MFTBC and Italy’s Fiat Powertrain Technology (FPT) and has cleared both companies’ strict criteria for quality, durability, and fuel economy. It carries the Mitsubishi Fuso brand and has been assigned MFTBC’s own model number. The 4P10 engine has been installed in Canter trucks in Europe since August 2009, ahead of application in Japan. FPT’s F1C model, the base engine for the 4P10 sharing the same structure, has been installed widely in many European commercial vehicles. Therefore, the reliability and actual performance are proven. |

Newly Developed 4P10 Engine |

|

||||||||||||

| Key Features/Advantages of 4P10 Engine: |

Planned compliance with the latest emission regulations in U.S., Europe, and Japan.

Piezo injectors adopted for common rail fuel injection system.

Variable geometry turbocharger adopted. |

||||

To achieve lower fuel consumption, high performance and clean gas emissions, a highly efficient variable geometry turbocharger is adopted. Keeping a flat torque curve and ensuring power at the high-revolution range, this component enhances vehicle drivability in an operating environment with repeated starts and stops, and therefore achieves clean and economic performance at a high level. |

||||

High efficiency EGR Cooler adopted. |

||||

For the exhaust gas recirculation (EGR) system, a high efficiency EGR Cooler is adopted to improve NOx reduction effect. Also the EGR cooler has been integrated with the continued-control EGR valve into one module, so much more space is saved in the engine design. |

||||

Environmentally-friendly green filter used as oil filter. |

||||

The engine’s oil filter has a new structure in which the outer case (housing) can be reused and the element only needs to be replaced, thereby reducing waste. |

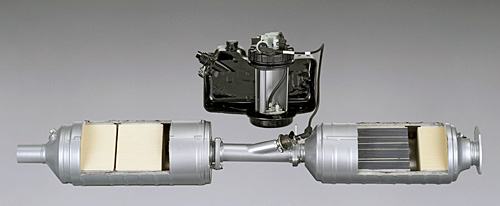

| 2. First use of BlueTec® emission system for light-duty trucks in Japan |

Hundreds of thousands of vehicles with the BlueTec® system are already running in the U.S. and Europe. In Japan, MFTBC has already adopted the BlueTec® emission system in several models, including the new Super Great heavy-duty truck launched in April, the Fighter mid-duty truck, Aero Queen and Aero Ace large tourist buses, and Aero Star large route bus. BlueTec® is a registered trademark of Daimler AG. In addition to MFTBC’s vehicles in Japan, the BlueTec® system is also installed in Mercedes-Benz passenger cars and trucks elsewhere, and is recognized worldwide as an environmentally-friendly exhaust gas after treatment system. Now, MFTBC is announcing that BlueTec will be installed in the upcoming new generation Canter. This will be the first case to use BlueTec® emission system for light-duty trucks in Japan, and together with the 4P10 engine with high combustion efficiency, the system achieves both fuel efficiency and emissions reduction in parallel. |

|

BlueTec® System |

| Key Features/Advantages of BlueTec®: |

| Achieving fuel efficiency and emissions reduction. | |

To preserve the global environment, MFTBC has adopted BlueTec® system (DPF + urea SCR) for light-duty trucks for the first time in Japan. This system is designed to overcome the traditional fuel economy penalty associated with NOx reduction, and achieve both fuel efficiency and emissions reduction. The system collects PM to be burnt for elimination through the regeneration DPF combining the oxidation catalyst and SiC ceramic filter. The BlueTec® urea SCR system - comprised of SCR catalytic muffler and an urea water dozing nozzle - decomposes remaining NOx into harmless nitrogen (N2) and water (H2O) through the chemical reaction of the ammonia which is generated from the urea water. With this BlueTec® system (DPF + urea SCR), the engine unit focuses on achieving high combustion efficiency, and PM and NOx emitted from the engine are eliminated efficiently by the after treatment device. Through this efficient distribution of processes, PM are NOx are reduced, fuel economy is improved, and CO2 is reduced due to fuel economy improvement. |

|

Regeneration DPF. |

|

The BlueTec® system has a regeneration DPF to burn and eliminate PM. Depending on continued burning function and PM accumulation/sediment, PM can be automatically burnt and eliminated in the filter. Frequency of manual regeneration (burning and elimination) is minimized, so drivers are not bothered by frequent manual operations for regeneration/elimination. |

|

AdBlue® and fuel consumption rate. |

|

AdBlue®, consisting of high grade urea water, is used as the NOx reducing agent in the BlueTec® system. AdBlue® is a registered trademark of the German Association of the Automotive Industry / Verband der Automobilindustrie (VDA). Its raw material is safe and harmless, widely used in products like cosmetics and has a broad production base in Japan. The AdBlue® consumption rate of the BlueTec® system in the new light-duty powertrain is expected to equal only 1-2.5% of fuel consumption. Consumption rate varies depending on vehicle specifications, payload and driving conditions. In the case of a 2-ton vehicle, the capacity of the AdBlue® tank is 12 liters, which means the operator will have to refill AdBlue® once every 4,000 km to 10,000 km. While the AdBlue® consumption represents an additional expense, the vehicle’s fuel economy is expected to improve 8-10% or more on average over the current JP05 model, through the combination of 4P10 engine, BlueTec® system, and DUONIC transmission. The above results are based on internal testing, and will vary depending on vehicle specifications, payload and driving conditions. |

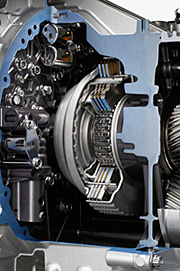

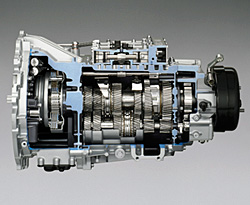

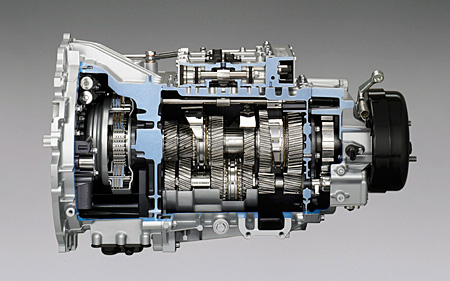

| 3. DUONIC dual-clutch transmission newly developed for application to commercial vehicles for the first time in the world |

MFTBC has been developing two-pedal automatic transmission for over 30 years. DUONIC achieves a direct acceleration feeling and smooth driving brought by the dual clutch, and also together with newly developed 4P10 engine, it significantly contributes to enhancing fuel efficiency. It combines the comfort of an automated transmission which the efficiency of a manual transmission. MFTBC developed the DUONIC design, built its control programs and also will produce and assemble the components. |

|

DUONIC Dual-Clutch Transmission |

| DUONIC Specifications |

Key Features/Advantages of DUONIC: Direct acceleration and smooth driving realized by dual clutch.

|

|||||||||

Excellent fuel economy with efficient power flow. |

|||||||||

The DUONIC gear change control adopts the fuzzy control MFTBC has nurtured over many years, and judges comprehensively the vehicle load, velocity, driving conditions and accelerator angle, enabling optimum control that the gear change is close to the driver’s will. The characteristics of the mechanical transmission with less power-delivery loss and appropriate gear selection by optimized gear change program enable fuel savings and powerful and comfortable driving. Also making good use of the advantage of no torque interrupt, an earlier shift-up in “ECO mode” is enabled to curb fuel consumption deterioration during heavy traffic. |

|||||||||

Wet-type dual clutch adopted with no need to replace clutches. |

|||||||||

DUONIC adopts a wet-type clutch that does not need regular clutch replacement. This eliminates the need of replacement due to wear of clutch disc will help deliver lower maintenance costs. |

|||||||||

Creep function added to realize easy drive same as passenger car. |

|||||||||

As a wet-type clutch has been adopted, a creep function has been added like with a torque converter AT. This makes it easy to control vehicle speed during fine-speed driving and hill starts. This provides easy driving and fine control over vehicle speed, similar to a passenger car. |

|||||||||

Parking range newly added. |

|||||||||

Parking range has been added to the transmission. By locking the gear inside transmission, the vehicle can be parked with ensured stability and safety. |

|||||||||

| Overall harmonized powertrain The above mentioned three components, 4P10 engine with BlueTec and Duonic, have been developed in parallel and have been matched to lead to an overall superior customer experience while achieving low emission levels and superior fuel efficiency. |

| About MFTBC

Based in Kawasaki, Japan, Mitsubishi Fuso Truck and Bus Corporation (MFTBC) is one of Asia's leading commercial vehicle manufacturers. In 2009, the company sold a total of about 99,500 vehicles including light-, medium- and heavy-duty trucks and buses. Daimler AG owns 85% of MFTBC shares and various Mitsubishi group companies own 15% of MFTBC shares. MFTBC is an integral part of the Daimler Trucks Division of Daimler AG. Mitsubishi Fuso is “All for you.” |

![]()

![]()