FUSO has long been a leader in electric mobility. Its eCanter, the Japan’s first series-produced electric light-duty truck, has been a reliable solution for city deliveries and short-haul routes. But when it comes to heavy-duty trucks—vehicles that travel longer distances and carry heavier loads—the path to zero emissions becomes more complex.

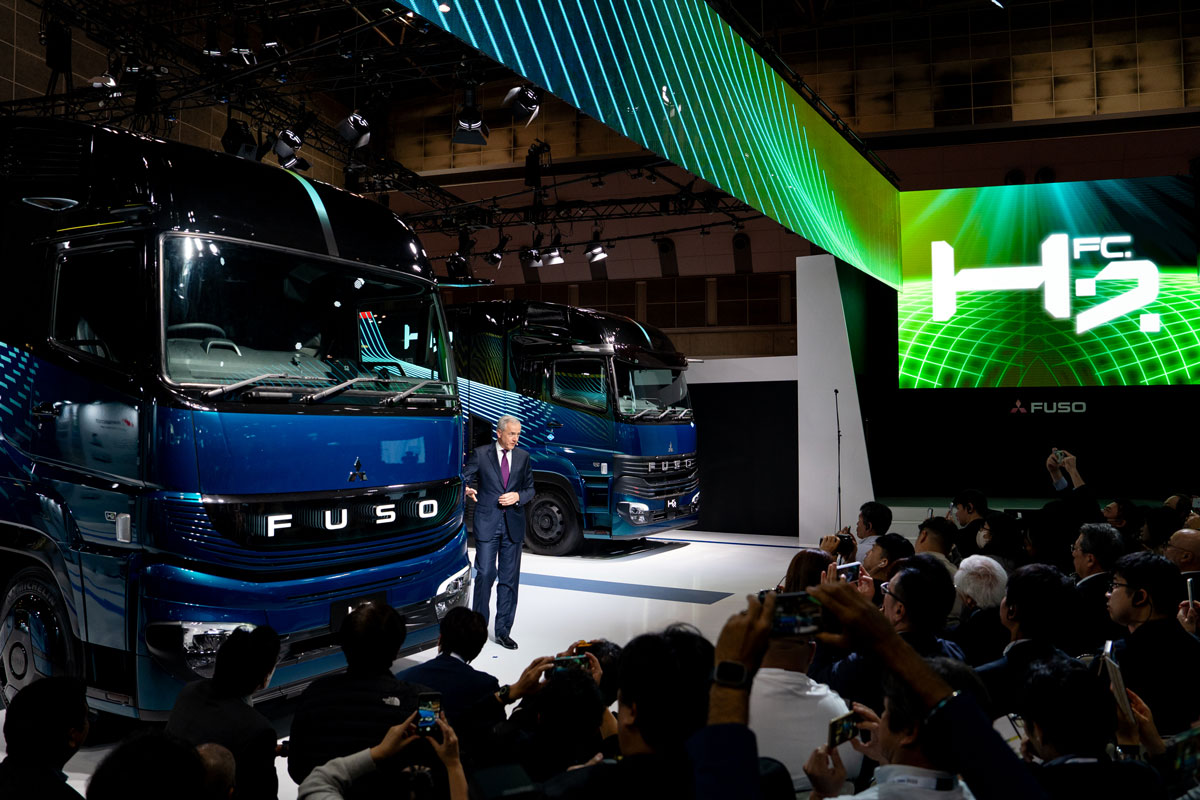

At the Japan Mobility Show 2025, FUSO is introducing two new concept trucks that explore how hydrogen could help meet the unique demands of this segment.

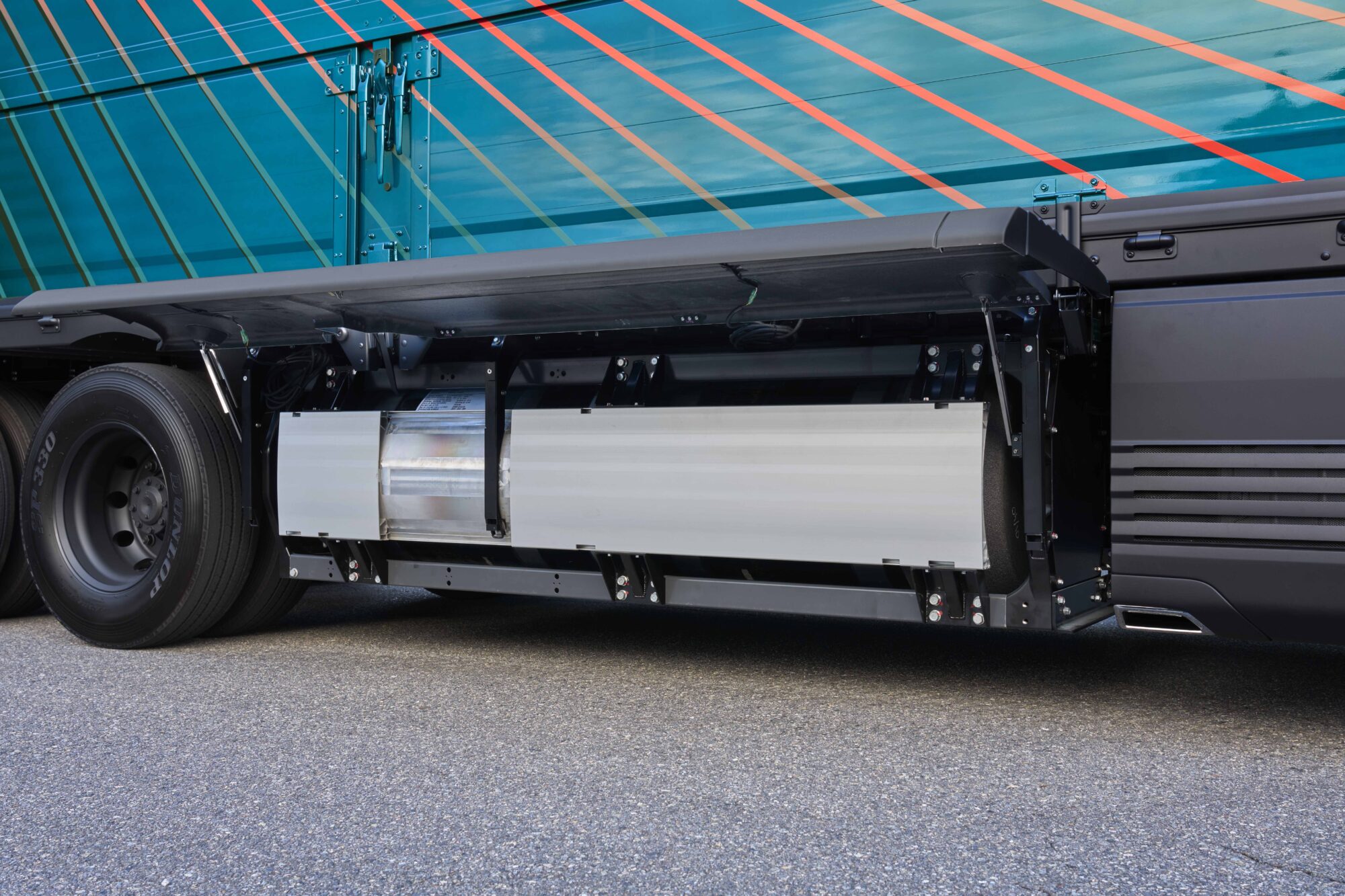

The hydrogen combustion engine-powered heavy-duty truck (H2IC) and the liquid hydrogen fuel cell powered heavy-duty truck (H2FC) represent two different approaches to the same goal: a cleaner future for heavy-duty transport.