Mitsubishi Fuso Quality Management:

Material Testing Services

Sorry. We did not find anything.

Material Testing & Analysis in Japan from a trusted OEM

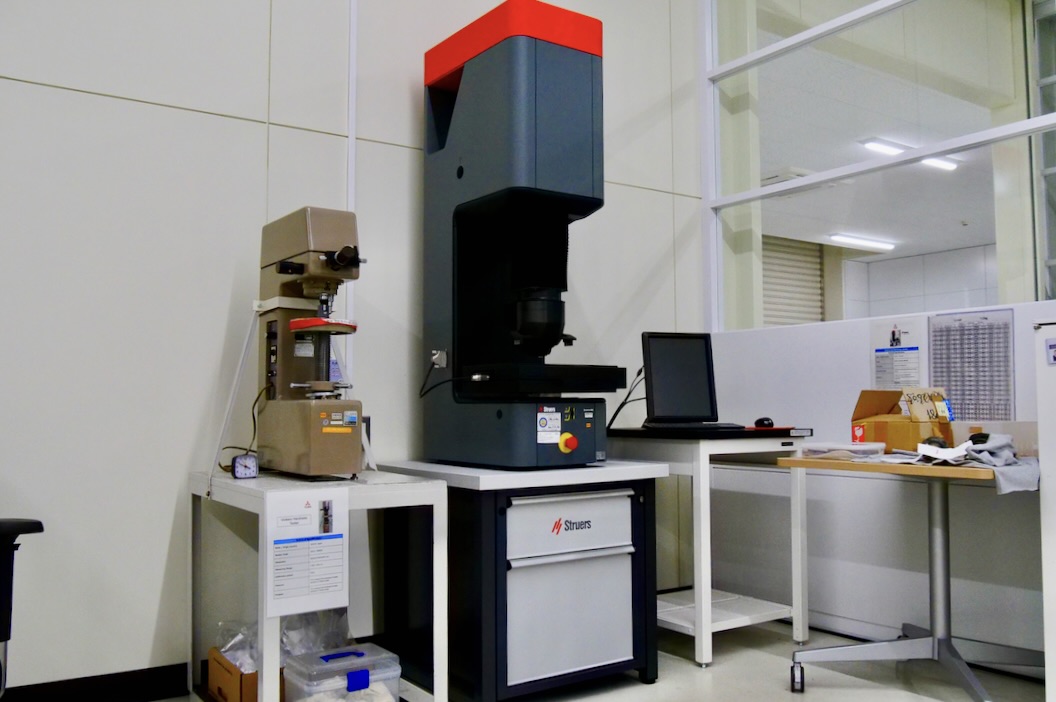

FUSO QM lab has been providing testing services for internal partners since 1970. Our experts test more than 1,500 parts annually among Daimler entities. Now our state-of-the-art testing facilities are open to the general public.

We provide certified ISO/IEC 17025:2017 standard testing with highly accurate, valid results. QM experts employ the latest version of the standard methods.

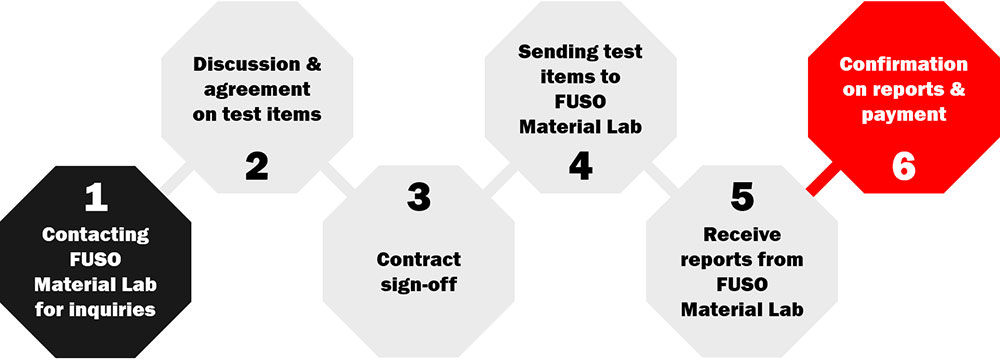

Contact us for your testing needs!

QM Lab’s core competency lies in failure- and root cause analysis of automobile parts.

Our ISO/IEC 17025:2017 accreditation scope includes metal hardness testing (Brinell, Vickers & Rockwell scales) and neutral salt spray test (SST), which is an extremely specialized competency.

Our state-of-the-art facilities and equipment enables us to offer your business a wide range of services:

Please use the below contact form to reach out to us for any inquiries. Our highly skilled engineers will be happy to provide guidance on test methods, parameters and answer any questions you might have.