Sorry. We did not find anything.

Mitsubishi Fuso undertakes its “IBL Control Tower” to digitally optimize domestic parts supply to production sites

- New system monitors the location of parts delivery vehicles and predicts estimated arrival times with AI

- Enhances work efficiency and minimizes risk of production adjustments due to parts delivery delays from vehicles carrying production parts

- AI algorithm jointly developed with student group at Sogang University, South Korea

- System to be deployed for vehicles delivering to the Kawasaki Plant in 2023

Mitsubishi Fuso Truck and Bus Corporation (Headquarters: Kawasaki City, Kanagawa Prefecture, President and CEO: Karl Deppen, hereafter “MFTBC”) has developed a prototype for its “IBL* Control Tower (tentative name)” system that digitally optimizes the parts import process for production sites. After a trial period, MFTBC will aim for the full-scale installment of the system in 2023.

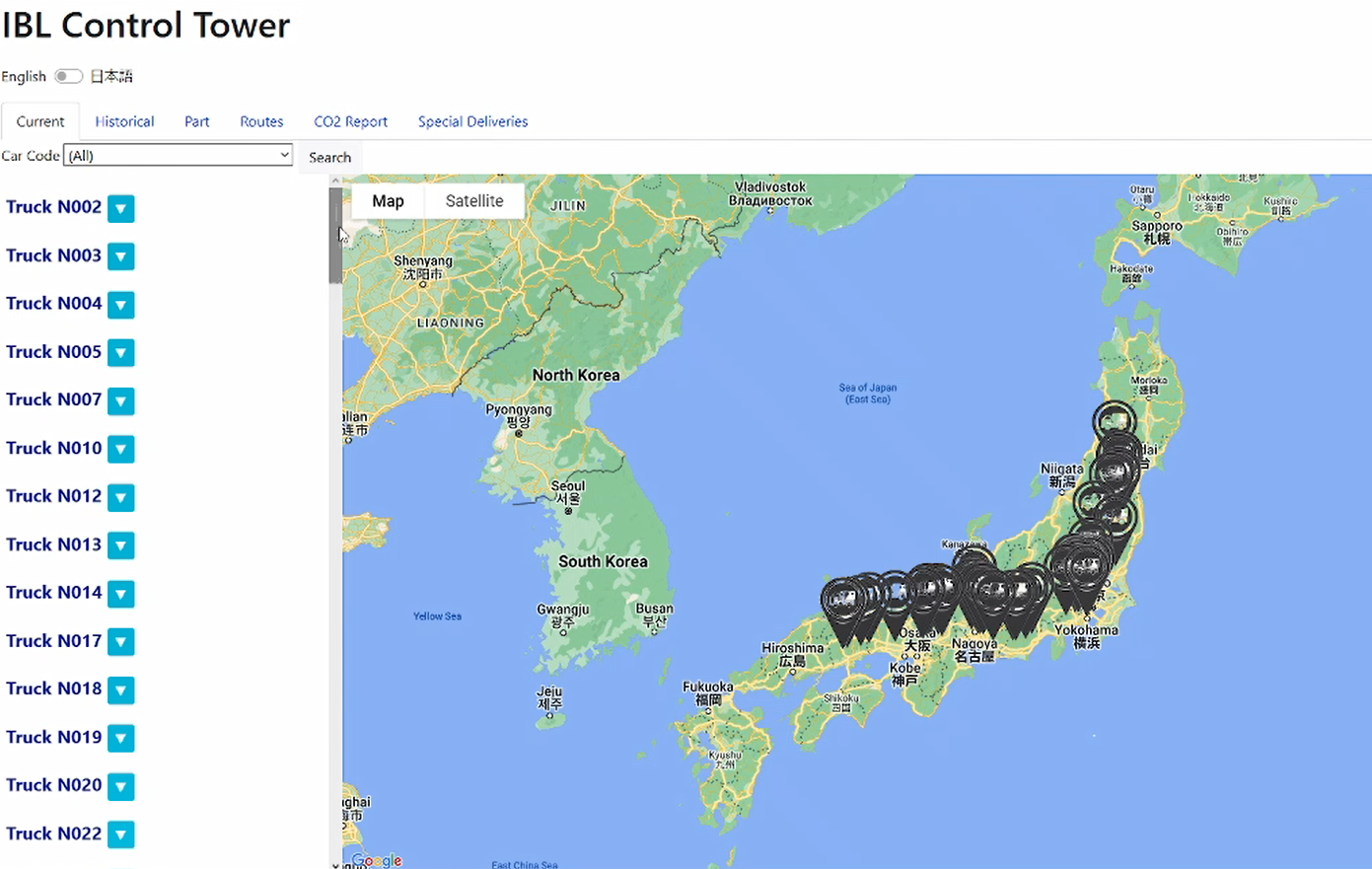

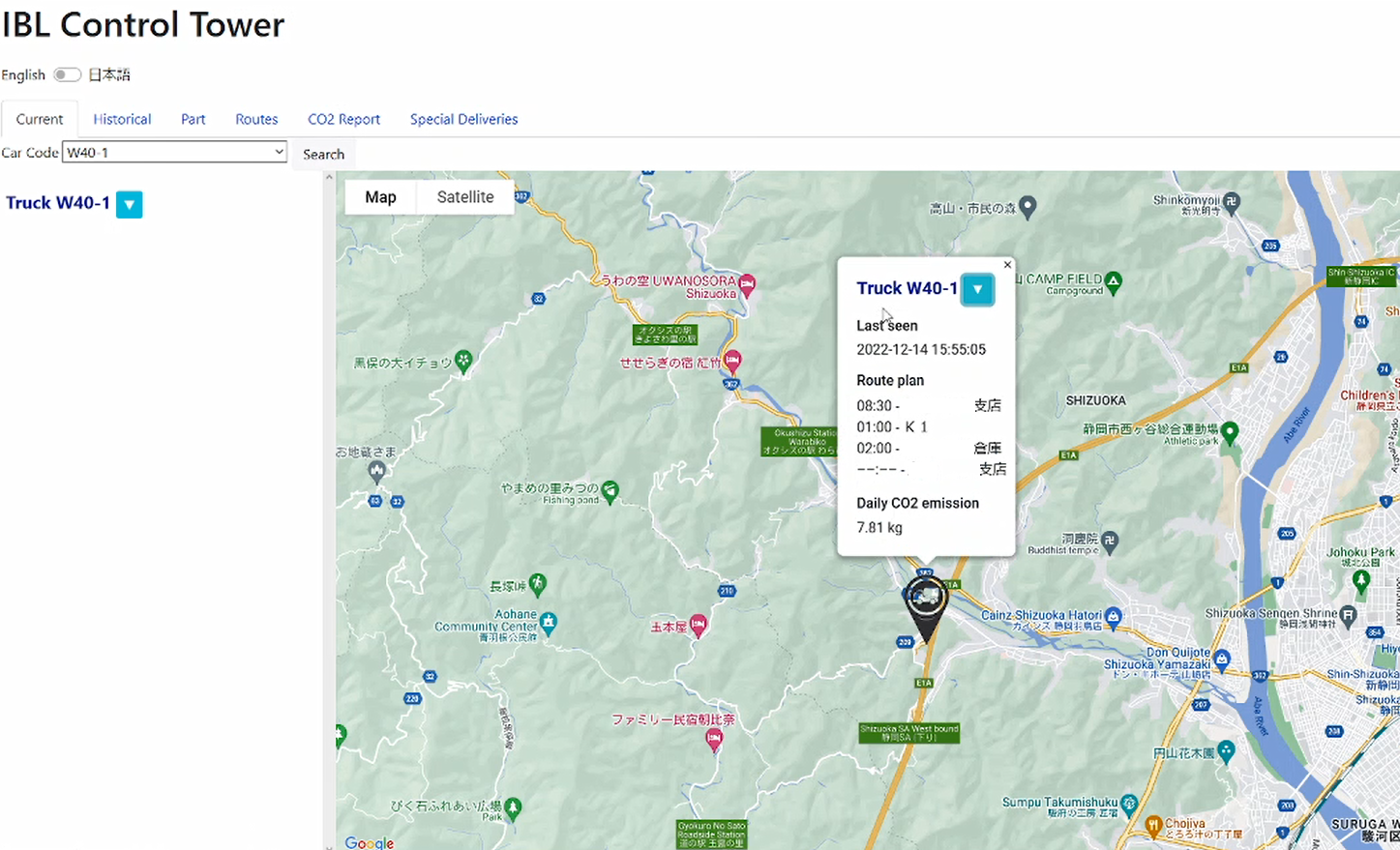

The “IBL Control Tower” is intended for vehicles (mostly trucks) that deliver parts to MFTBC’s production sites. A GPS transmitter is attached to each vehicle, through which the system acquires the location information of the vehicles, accumulating it in a database. Using this information, the “IBL Control Tower” predicts the arrival times of the vehicles with artificial intelligence (AI) technology that takes into account current and past location data and road traffic conditions. The accuracy of the prediction is within an error range of 10 minutes. Inbound logistics operators at the plant can thereby monitor the estimated arrival times of parts delivery vehicles and respond immediately in case of any delays. Moreover, the vehicle location data is shared with the logistics companies who own the incoming vehicles, additionally supporting their fleet management tasks.

Every day, more than a hundred parts delivery vehicles enter the Kawasaki Plant (Kawasaki City, Kanagawa Prefecture), where FUSO trucks and industrial engines are produced. By digitalizing the vehicle management process — conventionally conducted by telephone and e-mail — the “IBL Control Tower” is expected to lead to dramatic improvements in operational efficiency, while reducing the risk of production adjustments due to parts delays. The system is also able to continuously improve the accuracy of its predictions through data accumulation.

The development of the “IBL Control Tower” is part of MFTBC’s ongoing “Factory of the Future” project, which aims to improve the productivity and safety of production sites with cutting-edge technology. Within the framework of this project, the AI-based vehicle arrival time prediction algorithm has jointly been developed with the student team “Insight” from Sogang University (Headquarters: Seoul, President: Sim Jong-hyeok) in South Korea, with support from MFTBC’s open innovation platform “FUSO GreenLab”. MFTBC was able to shorten the development period for the “IBL Control Tower” through the efforts of the team contributing to the system’s algorithm.

MFTBC has started the final demonstration of this system from December 2022 and plans to complete the introduction in phases in 2023 with vehicles for the Kawasaki Plant. After a prioritized deployment for the Kawasaki Plant, MFTBC intends to expand the scope of the “IBL Control Tower” to vehicles entering other MFTBC bases in Japan, including Nakatsu Plant (Aikawa Town, Aiko County, Kanagawa Prefecture) which produces vehicle components, as well as Mitsubishi Fuso Bus Manufacturing Co., Ltd. (Toyama City, Toyama Prefecture), which is a wholly owned subsidiary of MFTBC and manufactures FUSO buses. In addition, MFTBC is developing a function to automatically calculate the loading efficiency of parts transport vehicles with an eye to optimizing the number of vehicles entering the site. Furthermore, acquired GPS data will be used as a basis for calculating the CO2 emissions for each truck with higher precision than otherwise possible.

Through the “Factory of the Future” project, MFTBC will continue to further streamline its production and related processes, improve safety, and aim to reduce production costs.

*IBL: Inbound Logistics

Demo view of the IBL Control Tower operator interface

About the “Factory of the Future” project

Beginning in 2017, the “Factory of the Future” initiative was set up to invest in automation, robotics and IT systems in further steering the plant towards Industry 4.0. This project uses cutting-edge technology to improve safety and efficiency in the production process, alleviate labor shortages, reduce production costs, improve productivity and the overall work environment. Initiatives such as digital end-of-line inspection and predictive maintenance using sensors on critical machines are just some of the examples of the improvements that have already been made. MFTBC is always dedicated to generating new ideas to further increase effectiveness and efficiency.

MFTBC at a Glance

Based in Kawasaki, Japan, Mitsubishi Fuso Truck and Bus Corporation (MFTBC) is one of Asia’s leading commercial vehicle manufacturers, with 89.29% of its shares owned by Daimler Truck AG and 10.71% by various Mitsubishi group companies. An icon in the Japanese commercial vehicle industry with a longstanding history of 90 years with its FUSO brand, MFTBC manufactures a range of commercial vehicles including light, medium, and heavy-duty trucks and buses, and industrial engines for over 170 markets worldwide. In 2017, MFTBC introduced the eCanter, the first all-electric light-duty truck in series-production and in 2019, the Super Great – Japan’s first heavy-duty truck fitted with Level 2 Automated Driving Support Technology, a benchmark in the Japanese commercial vehicle market. MFTBC operates under the umbrella of Daimler Truck Asia, together with its partner organization Daimler India Commercial Vehicles (DICV) in India. This strategic unit allows the entities to collaborate on areas such as product development, parts sourcing and production to provide the best value to customers.